e

Engine overhaul

Sooner or later, any engine—especially in a Soviet classic car—reaches the end of its working life. You may start hearing unusual noises, knocking, increased oil consumption, or experience irregular engine performance.

In such cases, full engine restoration—or as commonly called, a major engine overhaul—is required to restore factory-level performance. Even severely damaged engines from cars that appear rusted and deformed can be restored to original specifications and reinstalled successfully.

We don’t just repair engines—we restore them to original factory standards.

Main stages of classic engine overhaul in our workshop:

Engine Dismantling

Engine dismantling

Every restoration begins with careful dismantling. This stage is crucial to avoid damaging sensors, wiring, and the cooling system. Disassembly follows a precise sequence according to factory protocols.

Engine Cleaning

Thorough engine washing is essential. Dirt can distort measurements and settings in later stages. A clean surface ensures precision and reliability in the restoration process.

Engine Diagnostics

Defect inspection determines the exact cost of restoration and which parts need replacing. All components are sourced from certified suppliers only.

The diagnostic phase includes:

Crankshaft Inspection

We evaluate crankshaft wear—especially on journals—due to oil starvation or age-related damage.

Crankshaft Runout & Journal Wear

Crankshaft runout and journal diameters are measured and compared with factory tolerances. If deviations are found, we repair or replace the crankshaft.

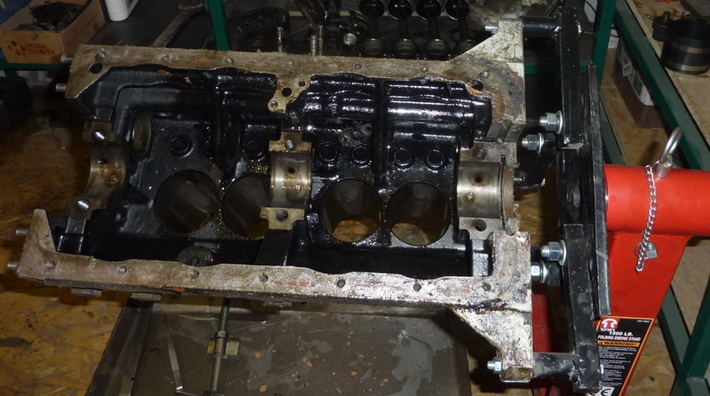

Cylinder Geometry Inspection

We use high-precision tools to check for cylinder bore deviations. If measurements exceed norms, we perform reboring or install sleeves.

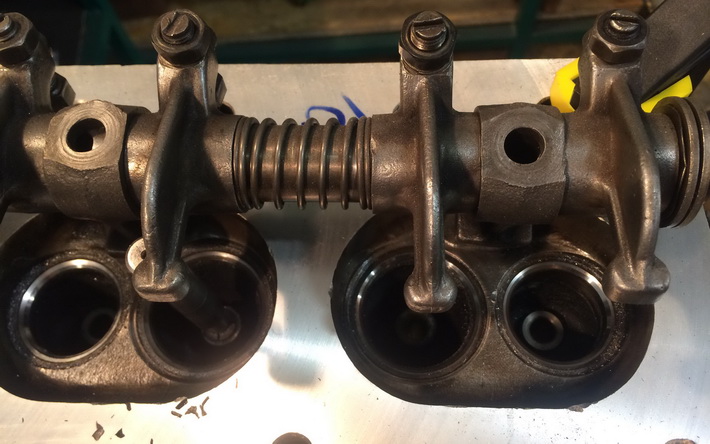

Cylinder Head Analysis

Cylinder head inspection

We inspect the cylinder head and valve gear for tightness, valve guide clearance, and camshaft-to-lifter gap.

Engine Restoration

From an engineering perspective, the process includes:

- Block restoration — sleeving, boring, and honing to fit new oversize pistons.

- Crankshaft bearing seat restoration — grinding, polishing of main and rod journals, and smoothing oil channel edges.

- Replacement of the piston/rod group

- Cylinder head reconditioning — including:

- Crack sealing via welding or other methods

- Replacing or re-machining valve guides, seats, and valves

- Deck resurfacing by milling or grinding

- Installation of new valve seals

- Camshaft and lifter replacement

Engine Assembly

Engine assembly

Assembly restores all tolerances and tensions to factory specifications. We strictly follow the correct sequence of operations and torque values using precision tools. Incorrect torque or assembly order can cause deformation and component failure.

During reassembly, previous steps are verified. For example, the crankshaft must rotate freely by hand—an indicator of correct bearing cap installation.

Test Run on Special Stand

Before final installation, the engine is filled with oil and coolant, then tested on a stand. We simulate all running conditions to break in engine components and record performance metrics.

Final Installation and Fluid Filling

The restored engine is carefully reinstalled. Only premium-grade technical fluids are used for long-lasting performance.

Each vintage engine requires a tailored approach. Our experts handle the most complex tasks—guaranteeing defect-free results with precision craftsmanship.