e

Encyclopedia of cars:

About Willys MB

Willys MB is an American off-roader, which was produced during the World War II (1941-1945). This model of military vehicles rolled off the assembly line of such factories as Willys-Overland Motors and Ford (having the other name - Ford GPW).

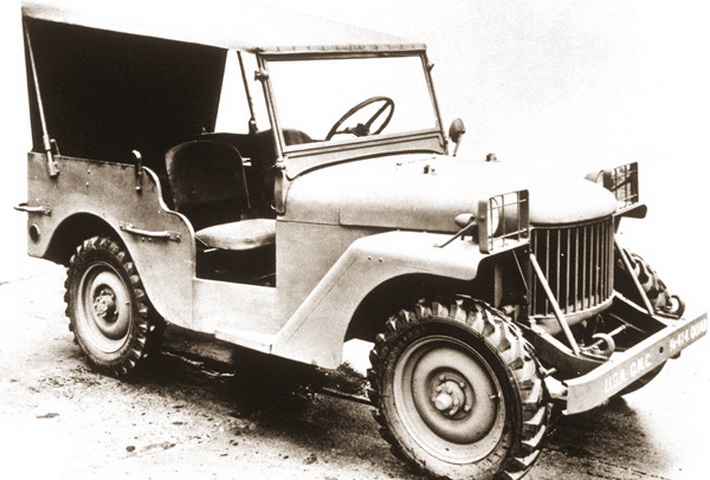

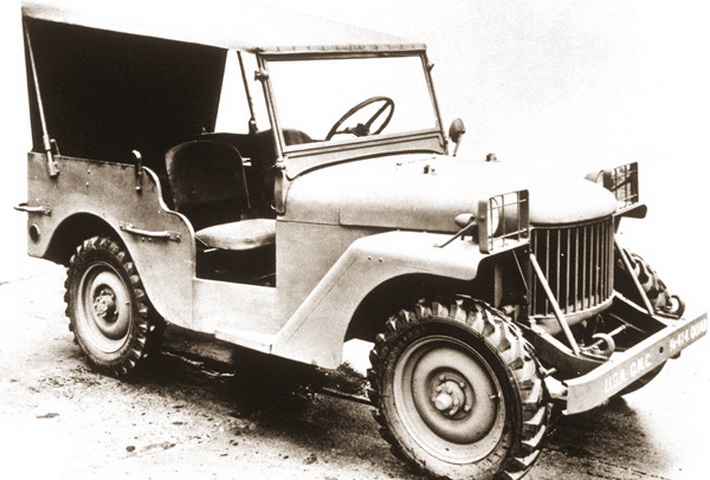

The first Jeep Willys MB

A bit of history about the first military off-roader

In the spring of 1940 the head of the US Army was given the task for the urgent production of a military vehicle with its further usage at the front. The problem was in very short terms and the specifications of the future "horse". It was strictly stated that the off-roader had to have a maximum speed of 80 km / h, to overcome deep fords - 29 cm, to drive on all wheels, the curb weight - not more than 585 kg, ground clearance - 16 cm, load capacity - not less than 270 kg. By the way, in the process of writing assignments the customers didn't want to make any concessions, although the weight was still reviewed to be more or less. The offers for the future manufacturing of vehicles were presented to about a hundred enterprises and only three of them took the risk to rescue their army. They were American Bantam, Willys-Overland and Ford Motor.

Early modification - Willys Quad, 1940

The first copy of the company American Bantam - off-roader Bantam BRC was presented after four monthes, it was created at the base of Bantam 60. Generally the engineers coped with the assignment, the only drawback was a strong deviation from the basic weight of the car. Despite it they still managed to produce 2,605 copies, but each of them was sent to the other continent. Not only the Commission, but also the experts from Ford and Willys were watching the test drive. At that time Willys copy was not yet fully ready. They had created a robust body structure, put a powerful engine, but hey failed to create a suitable suspension. After the engineers saw Bantam BRC with their own eyes, they decided to copy some elements and after a couple of months presented their own version of the off-roader.

Copy of Willys - Bantam BCR40

Test of BRC Bantam, 1941 (photo by Acme)

By the way, an interesting fact is that a few years later this "theft" of design and car performance from Bantam was officially proven by Willys. But at that time the company American Bantam did not exist any more, so the conflict quickly subsided. But back to the history ... Willys was also produced as very heavy vehicle (nearly 1,100 kg), so the model was upgraded in Willys MA and the weight was 980 kg. Approximately at the same time, Ford's off-roader Pygmy was presented and it satisfied the Commission as well. Drawing the results of the work of all three companies, the Commission stated its "satisfactory assessment" to all of them and allowed to make a small test batch of each of the copy. But the real "winner" had to be only one, so they had to choose ... Though Bantam BRC showed the best results in performance and steerability, respectively, its price was the highest as well. Ford cars were slightly cheaper, but Willys was the cheapest - only 738 dollars and 74 cents. All three cars were almost identical and differed only in small details, so the price, surprisingly, had the crucial role.

Drawing of military vehicle Willys MB

The contract was signed with Willys and after it produced the last copy of Willys MA, they immediately launched a full-scale production of Military Willys B series at the plant in Toledo. By the way, at that time, the company Willys did badly, and to be precise - they were on the verge of bankruptcy. It was very risky to sign a contract for the manufacture of such a huge number of cars, especially for such an important goal, that is why they sought the assistance from the Ford Motor Company and concluded a contract with them. Soon all the necessary documentation was submitted and they began to produce a copy of Willys - off-roader Ford GPW.

Development of amphibious vehicle based on the Ford GPW, 1941

These cars were not only used in domestic lands, but also were exported to the country's allies in large quantities. By the way, throughout the period of production about 52,000 copies were delivered to "Red Army", where they were used by commanders as reconnaissance vehicles or tractors of antitank cannons. 659,031 vehicles rolled off the assembly line, including Ford copies, many of them still exist.

The life of Willys MB at the front

Great Britain and the Soviet Union were the main "sales centers" of Willys MB. They were loved and respected, they progressed to the victory with their help and were always confident in their reliability and indestructibility. As a rule, the SKD vehicles in he special packages were delivered to the Red Army. It simplified the transportation and ensured their integrity. We can't say that they sent the ordinary boxes with "iron", because before sending each car was fully assembled and even taken through a small break in, and then again dismantled.

Tests of Willys MB at the Soviet test site

The Soviet Union began to receive the cars in the summer of 1942, after they went to the assembly line of Kolomna Plant #4 and to the Gorky Plant. A year later, the Soviet Union finally decided to test Willys MB. It was held near Kublinka Moscow Region at a large practice ground. The car came across very well, and even comparing it with the domestic GAZ-67, the soldiers pointed better hydraulics, easier handling and comfort. But the fact remains - Willys often got out of order, not even reaching 20 thousand mileage, and the reason for that was improper maintenance and low quality of gasoline. American cars differed with impeccable quality and durability, but in response they demanded the gasoline with an octane rating of at least 66 and a regular lubrication of components. In the Soviet Union these factors were often neglected and the lack of quality of raw materials made its impact as well.

In the Soviet Union Willys MB was often used as an antitank artillery tractor

Studying the history of the World War II and, in fact, the history of Willys MB, we can see this car in a variety of informal modifications that were altered "in their own way" by the Soviet engineers. For example the guns 12.7 or 7.62 mm, antitank cannons or the unique "reflectors" for the destruction of the German wire-traps were often attached to the car.

ATV Willys MB could overcome fords with a depth of 1.5 m

In 1943 popular Science magazine with the support of Congressman from Alabama Carter Malasko organized the competition for the best idea on the usage of the military Willys in peacetime in many different directions. The Vice President of Willis had even received a request for further cooperation, but the management did not see any prospects, and, in fact, wanted to move away from the production of off-road vehicles of this type, focusing on more sought-after types of vehicles. But in 1944 the situation had dramatically changed its direction when the presidency of Willys-Overland was taken by one of the former managers of the company Ford. He began to promote the adaptation of the American off-roader for agriculture and to promote «Station Wagon». Soon these cars were used by the American army and civil modification of Willys MB was named CJ1A, its mass-production started from the middle of 1944.

After the war Willys MB was widely used in agriculture

Technical and design features of Willys MB

The vehicle body was fully opened, supporting, with a relatively high boarding with four passenger seats. Bearing element of Willys MB was a frame of spar type. The axles of continuous type, equipped with interlocked differentials were connected to the frame through springs with shock absorbers of unilateral action. To ensure a good car weight distribution, designers installed the power unit longitudinally on the front wheelbase. As a result, the supporting elements of the body became perfectly smooth, a complete balance of the chassis was achieved and while moving the weight was evenly distributed on all 4 wheels.

Willys MB with a canvas awning, rear view

Another feature of Willys body was a complete absence of doors. This was done to ensure that in extreme conditions you could easily jump in or jump out of the car. Nevertheless, there was no danger, that you would not "fall out" of the body during driving, since the seats slightly sank in the cabin. Windshield, which was wide enough and had a sturdy frame, if necessary, leant on the hood. This "trick" was designed not only to comfortably aim and shoot ahead (especially when the weapon was massive and heavy, and it should be done while driving), but also to reduce the shape of the vehicle when it was necessary to lie low. And to make the vehicle practically invisible to the enemy, it was stained in a dark green color with special paint that did not shine in the sun. By the way, the designers had not forgotten about the wipers working on the engine. Many critics consider this detail was absolutely unnecessary and, considering the open body, there was a grain of truth in that. But we should not forget the fact that the car was equipped with a folding canvas top, which was stored folded in the back of the off-roader. It was used not very often, even at the bad weather. But in the absence of intense fighting, the soldiers still "sheltered" themselves and in that case they used the wipers.

Willys MB with a folded windshield

One spare wheel was attached behind the car. On the left side of the body you could see the tools needed in the field - an ax and a shovel, which were attached with special straps. Also on the left and the right side special holders were welded. They were made not for the convenience of the passengers, but if necessary, the car could be pulled out from ford or pit.

The interior itself was quite narrow and it seemed a bit difficult for a driver to get into the car. But in the time of war the comfort was afterthought, taking into account more important tasks. As for the driver's seat, narrowness in combination with a thin three-spoke steering wheel of a sufficiently large diameter, allowed to be more confident on the roads, to hold the steering wheel tight and not to lose control, bumping over large rocks or hills.

Gasoline tank was located under the driver's seat, and you had to swing the pillow to fill up the car. There was a sofa without arms behind, but on both sides (behind the rear wheel arches) there were a kind of glove compartments for tools and the other equipment. Front wheels did not have arches and there was quite big gap between them and the hood. Instead of the front bumper wide and thick sheet of metal was welded, which came forward for 30 centimeters. This was done to overcome obstacles without damage to the vehicle (e. g. shrubs, sticks, high weeds, etc.) or the soldiers could effortlessly pull the stuck vehicle out attaching the wire to the frame. The radiator grille had a lot of thin vertical spokes, and the headlights were slightly drowned in it. This was required by its distinctive design, which allowed to raise the lights and to turn their lenses down (it was especially useful during the night repair of the engine or to move without additional devices of blackout). In the early spring of 1942 the grille had already had seven spokes and stamped lining, and after 5 months the auxiliary lights with "peak" and a protective metal ring in front appeared on the left wing.

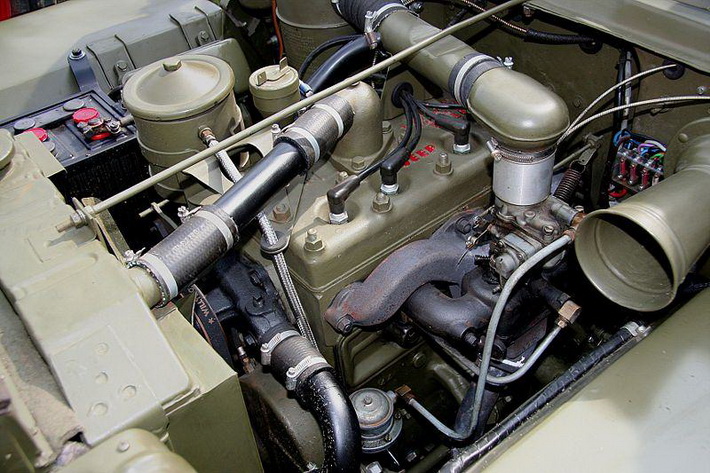

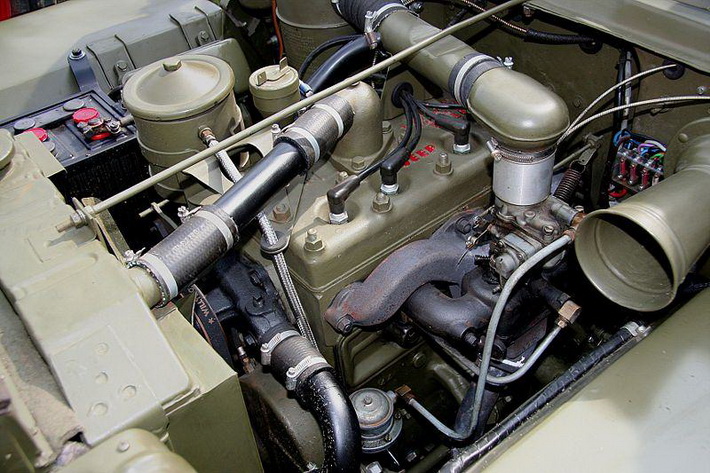

And now the most interesting is the "heart" of this military “beast”, which is recognized as the most long-stroke in the world. The four-cylinder in-line engine had a capacity of 2199 cc and a power of 60 hp. It was refueled with gasoline A-66 and in spite of the highest quality and durability it was very sensitive to low-quality gasoline, because of this it could quickly get out of order. As for the manual transmission, it was a three-stage and fully interlocked with the engine itself. On the 2nd and the 3rd stage the synchronizers were installed, but the torque divider was connected to the gear box. Thanks to the cardan shafts with hinges, the power was evenly distributed over the back and the front axles.

Engine of Willys MB

The car could be driven not only with a single lever of the gear box, but with two more levers - the torque divider levers, one of which was used to connect the front axle, and the other - to interrupt or downshift. Braking system was hydraulic and was extended to 4 wheels, which was a great virtue. Despite the fact that all the wheels were leading, the engineers did not provide the differential between the axles for some reason, so the moment between the front and rear axles was not distributed. The pull was distributed only among the wheels by usual conical differentials without blocking knots. Since the car was designed for the most demanding and extreme conditions, it had to overcome deep fords, which in some cases reached almost half a meter. Therefore, the designers decided to make drain hole at the bottom of the body, which was closed with a plug.

Specifications of Willys MB

| Years of production | 1941-1945 |

|---|---|

| Body | integral, open, without doors |

| Dimensions (L / W / H) | 3335/1586/1830 mm |

| Weight | 1020 kg |

| Load | 250 kg (with driver and passenger - 363 kg) |

| Axle load (front / rear) | 505/515 kg |

| Maximum speed | 104 km / h |

| Fuel consumption | 13.2 l / 100 km |

| Angles of drive / ramp | 45/35 degrees |

| Towable weight (max) | 453 km |

| Turning radius | 5.3 m |

| Engine | 4-cylinder, gasoline, L-head |

| Bore diameter | 79.37 mm |

| Engine dimensions (d / w / h) | 680/570/670 mm |

| The working capacity | 2.2 liters. |

| Maximum power (at 3600 rev / min) | 60 hp |

| Compression ratio | 6.48 |

| Operating procedure of cylinders | 1-3-4-2 |

| Lubrication system | mixed |

| Oil pump | geared, with internal gearing |

| Cooling system | water, with forced circulation |

| Fan | 4-bladed, with a V-belt of a runner |

| Water Pump | Centrifugal |

| Model of carbureter | "Carter" model WO-539-S |

| Fuel Pump | Diaphragm |

| Air filter | with oil bath and filter gasket, model A-19386 |

| Fuel filter | plate with a sump |

| Clutch | single plate, dry with shock-absorbing springs |

| Transmission | Manual, 3-speed |

| Drive gear | hypoid, single, with conical gears with spiral teeth |

| Torque divider | Manual, 2-speed, with a splitter |

| Drive shafts | Hard, tubular, with needle bearings |

| Axle rear / front | drive with balanced axles |

| Wheels | disc |

| Tire size | 16 inches |

| Suspension | longitudinal, with semi springs (4 pcs) and double acting hydraulic shock absorbers (4 pcs) |

| Steering wheel | Three-spoke worm, model T-12 |

| Brake pedal / hand | hydraulic, pad, 4 wheel / Mechanical, belt |

| Frame | stamped, riveted |

The main differences between the cars Ford GPW and Willys MB

Externally, these cars were almost identical, both versions were called Willys in the Soviet Union, but in fact they had a number of differences that were evident not only in the technical but also in the structural part. In fact, in order to identify a particular model, it takes more effort, as not everyone knows that a range of Willys MB as well as a range of Ford had three versions: early Willys (November,1941-March,1942), standard Willys (March,1941 –December,1943) and composite Willys (December,1943-October,1945); standard Ford (April,1942-December,1943), transition Ford (December,1943-January,1944) and composite Ford (January,1944-June,1945). The absence of precise data about the date of change or the introduction of new parts gets some additional complexity. For the following four years Willys and Ford were constantly upgraded, so it is impossible to compare them with the maximum accuracy unfortunately, but they succeeded to get some main differences.

Restored Ford GPW at the exhibition

Lets take the frame first: Willys had I-beam axle of a tubular shape, rectangular-box-shaped shock mounts, while Ford’s axle was rectangular (like an inverted letter U), its brackets were in the form of an overlap. The stand for the battery had differences as well – Willys had in a form of rectangular metal layer and Ford’s had an additional oval hole in the center. Comparing both cars, you can see the difference of the license plate of frame and engine. By the way, it was possible to determine the car the most accurately by the number of the engine: Willys’s number consisted MB index and six digits, while Ford GPW - GPW index and the same six digits.

Regarding the body, it was a little bit more difficult. Since early Willys had relief stamping of its name on the back of the body, the radiator consisted of 10 spokes and the glove compartment was missing. The stamping of the standard Willis was on the wheel arch under the lock of the niche for the tools. It had a glove compartment, the bottom of the two reinforcing ribs, leg support and a rectangular rear seat bracket. As for Ford, its "standard" modification had the front support bracket of ACM II type, there was no number, the stamping of the name was in the wheel arch under the lock of the niches, the logo was on the rear panel, the rear seat had a triangular bracket, the rear lights had vertically mounted brackets. Furthermore, compared to Willys, early models of Ford had glove compartment and a bottom with two reinforcing ribs, a footrest for rear passengers. Transitional Ford got a triangular power of rear body panel, the right arm was installed at the back seat, but the stamping of the name of the car disappeared from the sides of the wheel arch on both sides of the rear seat bracket. The exact modifications that have occurred regarding the composite Willis and Ford were unimportant, so they can be omitted.

Interesting facts

- The engine of Willys «Go-Devil» set a new world record for the "long-stroke", because its piston stroke was 111.1 mm, the diameter of the cylinder just 79.4 mm.

- During the test of Willys in the vast Soviet Union it showed poorer performance than had been claimed by the manufacturer. This case concerned the torque and of the power that was barely 56.6 hp. The reason for all this was the regular usage of the lubricants of very poor quality.

- The front dash-board had a special metal plate, where the permitted speed was depicted. For example, if you activate the "downshift" during forward movement, it slowed down the car in 2 times and at a down-level in the mode of reverse movement the speed should be no more than 9 miles / hour. By the way, when driving on hard surface (asphalt), it was not recommended to connect the front axle.

- In the following years all off-roaders of Willys acquired a new name - Jeep, which appeared as a result of listening (audition) a combination of the words «General Purpose».

- The off-roaders of Willys MB were shipped in bulk to various allied countries. But these were neither "gifts" nor help and not for sale. Cars were available for rent and after the war the US government announced to return Willys intact and in good condition.

- American Willys was admired by almost the whole world and now these cars can travel with confidence the most severe off-road. As a result, after the war, some countries “obtained by request” the right to produce the license copies under their own name (French Hotchkiss, Japanese Mitsubishi, Spanish Ebro, etc.).